Work order management: A complete guide for 2024

Apr 15, 202413 MIN READ

What is a work order?

A work order is a structured request for a task, project, or job, serving as a clear directive in both external customer engagements and internal initiatives. It outlines necessary actions, responsible parties, timelines, and resources required, which are vital in managing tasks and ensuring accountability and clarity in various sectors.

Work orders are a key component of the computerized maintenance management system (CMMS). A properly executed maintenance work order can solve a need (often an emergency) and provide sufficient data for analytics to improve operations.

This guide provides a straightforward understanding of work orders, emphasizing their practicality in ensuring organized and efficient operations.

How is a work order different from a work request?

A work request identifies a problem to be solved. A work order authorizes the solution, typically identifying the assets and costs associated with the remedy with sufficient detail to act as a single point of reference for all parties and follow-up performance measures and analysis.

How is a work order different from a purchase order?

A work order is an internal document that authorises and details tasks such as maintenance or repairs within an organization. In contrast, a purchase order is a formal external document sent from a buyer to a seller, specifying types and quantities of products to be purchased, often becoming a legally binding contract upon acceptance.

Work order process

Sometimes referred to as lifecycle, there are various steps a properly composed work order goes through for completion:

1. Identify the task

The initial work order process step involves clearly defining what needs to be accomplished. This could range from maintenance, to a client request, or an internal project. Accurate task identification is vital to the success of the following steps. Think of this as a ‘problem’ identification.

2. Evaluate a work request

The department responsible reviews the task to determine if it can be completed and the personnel and resources needed.

3. Create the work order

At this stage, the task is outlined in detail, including descriptions, resources needed (both staffing and materials), time estimates, and costs. This clarity is essential for guiding all parties involved in the work order process. It includes:

Approval: Approval ensures the work order aligns with business objectives and is feasible in terms of resources and timelines.

Priority: Ensures critical tasks are addressed first, based on factors like urgency, customer impact, or resource availability.

Assignment: To the appropriate team or individual, matching the task's requirements with the skill sets available.Distribution and Execution

4. Distribution and completion

This involves the practical implementation of the plan, ensuring the assigned teams execute the work order effectively. This typically requires monitoring of planned versus actual progress and updates in response to challenges.

5. Closing and documenting

This critical step often needs to be completed more. The workers should provide sufficient detail so that the work can be evaluated against goals and guidance for future actions: materials and equipment used, images, and notes.

6. Review and analysis

Evaluating the achieved outcomes against the planned objectives provides insights for continuous improvement. Long-term, aggregated work orders may reveal opportunities for improvement or equipment life cycles that need to be addressed. For example, analyzing the pattern of breakdowns in hydraulic pumps by analyzing associated maintenance work orders may suggest the need for alternative sources.

What should be included in a work order?

Work orders that can vary by industry and company. As a rule of thumb, more detail is better. Digital work orders can simplify the user interface, highlighting the critical information needed within an enterprise and ensuring the required information is available. Here is a list of recommended information fields that help track progress and enable long-term analytics to improve overall efficiencies and lower costs.

Order ID: A unique identification number for each work order request, ensuring easy tracking and reference.

Title: The name assigned to the work order, such as "Heating Issue," provides a quick overview of the task.

Date of Request: The work order was initiated or raised.

Problem Description: A concise summary of the issue or request, such as "Cooling unit of the engine not running at full power."

Asset: Specifies the particular asset(s) requiring attention or repair, like an AC unit or Material Handler in a warehouse.

SLA (Service Level Agreement): The promised time frame for the service teams and technicians to complete the maintenance work.

Cost Estimation: A detailed breakdown of all expenses related to the work order, providing financial clarity.

Category: Defines the type of work order, which varies based on the company and industry.

Status: Indicates the current phase of the work order, with common statuses including "Assigned," "In Progress," "Re-opened," and "Completed."

Priority: The urgency level of the work order, typically categorized as high, medium, or low.

Customer Info: Information about the customer or stakeholder who initiated the service request, including name, contact details, and location.

Technician Assigned: The name and details of the technician responsible for fulfilling the work order.

Additional Documents: Any supporting documentation or files necessary to complete the tasks outlined in the work order. Modern work order management systems today enable access to attached files, links to information resources like replacement parts, LOTO instructions and how-to instructional PDFs. A skillfully designed user interface can ‘hide’ the info until needed.

Each of these elements plays a vital role in the clarity, efficiency, and successful execution of a work order. Other field-searchable information can be added as required.

Key participants in crafting a work order

Creating an effective work order involves a team effort from various departments to ensure its accuracy and completeness. The primary contributors may consist of:

Requestor/Customer: Initiates the work order by identifying and describing the need or issue.

Facility or Operations Manager: Validates the necessity of the work order and its alignment with operational goals (think: facilities management).

Maintenance Manager/Supervisor: Reviews and refines the work order details, focusing on the scope, resources, and prioritization.

Technician or Specialist: Provides technical expertise and estimates on time and resources required for task completion.

Safety Officer (if applicable): Ensures inclusion of all relevant safety protocols and procedures.

Finance Department: Assesses and approves the financial aspects, especially in cases of significant expenses.

IT Support (for digital systems): Facilitates the accurate and efficient capture of work order information in digital platforms.

Quality Assurance Personnel: Ensures the work order meets the necessary quality standards and specifications.

External Vendors/Contractors: Contribute to the work order when external services or expertise are needed.

This collaborative approach ensures that a work order is well-rounded, and feasible and sets the stage for effective execution.

Types of work orders

Inspection work orders

Inspection work orders focus on regular assessments of equipment and facilities. Their primary purpose is to identify current or potential issues that could lead to bigger problems if left unaddressed. This type of work order is crucial for maintaining safety standards and ensuring equipment longevity. It is usually executed by a maintenance team and maintenance technicians.

Preventive maintenance work orders

These work orders are scheduled tasks aimed at preventing equipment failure before it occurs. They can involve routine maintenance tasks or activities based on specific time intervals or usage patterns. The goal is to reduce equipment downtime, avoid costly repairs, and extend the life of assets. Or commonplace requests like regularly scheduled spray or pest control around a property.

Emergency maintenance work orders

Emergency work orders are critical and require immediate attention. They arise from unexpected issues that disrupt normal operations, like equipment breakdowns or system failures. The focus is on quick response and resolution to minimize operational disruptions and potential damage.

Corrective maintenance work orders

Corrective maintenance work orders are reactive, and initiated after a problem has been identified. They include actions like repairs or replacements to fix the issue and restore equipment or system functionality. This type of work order is essential for maintaining operational efficiency and productivity.

General work orders

Work orders that don’t belong in the other categories noted above. Electrical work orders to add resources are a common example as information-processing needs accelerate in a cloud and AI-driven future.

Benefits of work order management

Work orders serve as essential tools in different sectors, streamlining processes and enhancing operational effectiveness. Here's a look at their benefits through real-world scenarios in various industries.

Increase efficiency

In a manufacturing setting, like an automotive parts factory, work orders detail every aspect of production, from materials to assembly timelines. This work order process system ensures clear tasks, reducing downtime and increasing production efficiency. For instance, when producing car engines, the work order specifies parts and quantities, enabling a smoother workflow and timely completion. These include a due date (or expected completion date), predictive maintenance tasks, and more.

Optimal inventory management

For a logistics company, work orders are crucial for managing inventory and ensuring timely deliveries. Consider transporting electronic goods; the work order includes details like storage conditions and transport schedules, allowing for precise planning and execution. This leads to reduced errors, safer handling, and higher client satisfaction.

Streamline operations

In property management, such as a residential complex, work orders facilitate efficient maintenance scheduling. Residents' requests are systematically converted into work orders, ensuring timely and organized responses, from landscaping to electrical repairs. This work order process maintains property conditions and enhances resident satisfaction.

Enhanced accountability

In construction, the help desk with work orders provides clarity and coordination for complex tasks. Each work order outlines specific responsibilities, timelines, and resources for a commercial building project, improving task completion and problem-solving efficiency. This leads to on-schedule project delivery and increased stakeholder trust.

Ensuring compliance

In industrial environments like oil refineries, work orders are integral to safety. They include detailed safety checklists for tasks such as equipment inspection, ensuring adherence to safety protocols. This reduces accident risks and ensures regulatory compliance, safeguarding employees and the organization.

The benefits of digital work orders vs. paper work orders

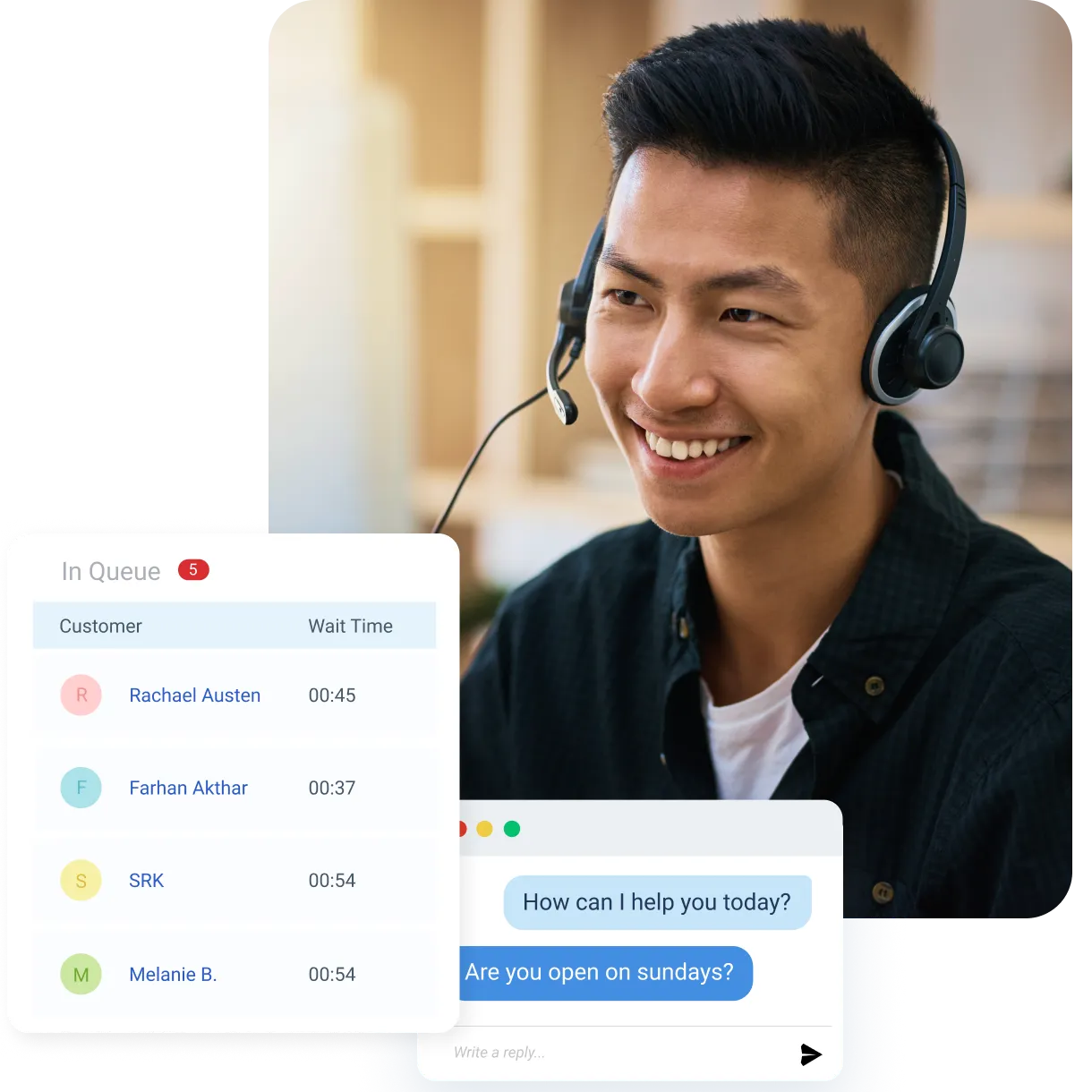

The transition from paper to digital work orders represents a significant leap in operational efficiency. Their positive impact on customer relations cannot be emphasized enough:

Enhanced Efficiency and Speed: Digital work orders streamline the entire work order process at every step, enabling faster creation, distribution, and completion than manual paperwork.

Real-Time Updates and Communication: They allow instant updates and communication, ensuring all parties are informed of status changes in real-time.

Accessibility and Mobility: Digital work orders can be accessed from anywhere, offering greater mobility and flexibility for users.

All the necessary data at one’s fingertips. Field engineers can access multiple data sources associated with a work order to gain insights, instructions, procedure checklists, and safety information.

Improved Accuracy and Error Reduction: Digital formats reduce the likelihood of human errors and provide more accurate data capture.

Easier Tracking and Management: Digital systems enable easy monitoring and management of work orders, simplifying task tracking and oversight.

Data Security and Confidentiality: They offer enhanced security features, protecting sensitive information more effectively than paper documents.

Scalability and Customization: Digital work orders can be easily scaled and customized to fit the evolving needs of a business.

Comprehensive Reporting and Analytics: These systems facilitate detailed reporting and analytics, providing valuable insights for decision-making.

Integration with Other Digital Systems: They can be seamlessly integrated with other business systems, streamlining workflows and data sharing.

To sum it up the transition to digital work orders is imperative for any service organization needing to maintain a competitive advantage and high customer service standard.

Work order best practices

Define goals, measures of success and system standardization

If you’re setting up a new work order management system or modifying one, always start at a high level with input from key players. Typically this means setting good standard operating procedures, agreement on metrics and KPIs, and identifying key players and roles. It also defines the work order process from task identification through completion and analytics. In this information-rich era, think beyond the initial work request to how a consistent and determined tracking of incidents can improve your entire organization. Properly documented work orders can.

Go digital and mobile

Paper-based work orders are so Y2K. Cloud-based data storage, mobile access, work order input and retrieval in real-time are truly revolutionizing remote, in-field operations, maintenance and repair. Today customer satisfaction is based as much on anticipating their needs as meeting them. A well-designed work order system running on a SaaS cloud platform like Freshdesk® can help build customer loyalty to a level most enterprises just dream of. How? Consider:

Your service and field teams share simplified task management, dashboards, and automated workflows.

Field techs can navigate to sites, remotely receive new work orders, make notes, and record customer sign-offs, and images of work.

All stakeholders, including customers, benefit from this integrated and real-time work order reporting. When it’s done, you know it’s done, and so do your customers.

Imagine, anticipate, and prepare proactively

Who doesn’t remember “an ounce of prevention is worth…” Are there remote monitor setups that automatically trigger work requests and responses? Are preventive maintenance schedules in place? Should we anticipate and regularly schedule machine change-out and/or software updates? Today’s work order process systems must anticipate and prepare for the benefits AI will bring with an open and flexible architecture that keeps and builds on today’s best practices.

Details matter

Cloud-based systems put lots of information at a viewer’s fingertips. Don’t skimp on and the details. A good user interface helps navigate from high-level views to rigorously organized details. Drop-down menus, look-ups, access to online schematics, inventory, replacement parts, and even safety procedures can be viewed. Procedure checklists to minimize human error are a welcome addition. Ideally, all the information needed on-site can be available offline for look-up in off-internet locations too.

Plan for the future

Change is gonna come. Build flexibility into your ticketing system to allow for it. At Freshworks we encourage hyper-detailed work orders with a flexible data schema that allows for big-data analytics and a future-proof architecture. We’re building in cloud-based flexibility, workflow automation and other features in a simple and intuitive design. You should expect the same from any work order system service provider.

Seek work order management systems that raise productivity and service excellence

Partner with a forward-thinking software company with a track record of innovation. With AI just beginning its inevitable penetration, seeking a company with the scale to succeed in its complex implementation is important. You should expect at minimum functionality that boosts your competitive advantage and customer loyalty. Expect tools like these that deliver:

Easy scheduling with an integrated dashboard that combines drag and drop controls with calendaring to show all service tasks, their current status, and the technician assigned.

Customized dashboards with reporting to gain insights into the overall performance of field operations, and status, plus detailed metrics such as first-time fix rates & work order volumes.

Customized service task management to build your groups of internal and external agents and contractors with group-based scheduling, work order creation, and flexible information input like deadlines and priority.

Examples of work orders

Manufacturing: maintenance work order management software is used to schedule and track maintenance of machinery and equipment. It helps in organizing routine checks, and urgent repairs, and ensures minimal downtime in production lines.

Healthcare: Hospitals and clinics utilize work order management software for maintaining medical equipment, managing repair requests, and ensuring compliance with health and safety standards. It's vital for scheduling preventive maintenance to keep medical devices in optimal condition.

Facilities Management: This industry uses the help desk software to manage and execute tasks like building maintenance, HVAC system repairs, and cleaning services. It helps in efficiently handling requests, scheduling services, and ensuring the smooth operation of facilities.

IT and Telecommunications: Work order management software in these sectors is used for managing network maintenance, and software updates, and hardware repairs. It ensures timely responses to system outages or technical issues, maintaining service continuity.

Construction: In construction, the software is used to manage various project stages, allocate resources, and track progress. It’s essential for scheduling tasks like site inspections, equipment maintenance, and coordinating subcontractor activities, ensuring projects stay on track.

Conclusion

A well-designed work order system is crucial for modern businesses, offering multiple benefits: streamlined operations, enhanced profitability, and strategic long-term planning. Going digital and mobile drives even greater long-term benefits. More improvements are on the way as AI penetrates further into automation and corporate work order best practices. Moreover, the integration of big data analytics transforms these systems into powerful tools for strategic insights, enabling businesses to identify trends, anticipate market changes, and uncover long-term opportunities. This comprehensive approach not only elevates immediate operational effectiveness but also positions businesses for sustainable growth and competitive advantage in a customer satisfaction-driven market.